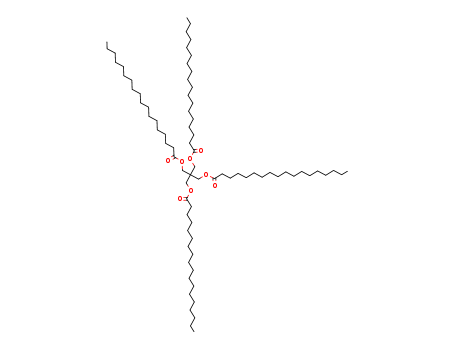

Pentaerythrityl tetrastearate literature

A mesoporous SnO-γ-Al2O3nanocomposite prepared by a seeding-crystallization method and its catalytic esterification performances

Cui, Mingyu,Ding, Jianfei,Ding, Wei,Shao, Rong,Wang, Lizhi,Wang, Yuan,Xu, Wei,Zhang, Yidong

, p. 14797 - 14802 (2021)

A mesoporous SnO-γ-Al2O3 nanocomposite was synthesized by a seeding-crystallization method and investigated in catalytic esterification of pentaerythritol and stearic acid to produce pentaerythrityl tetrastearate. SnO-γ-Al2O3 prepared by conventional hydrothermal synthesis was also examined for comparison. The catalysts were studied using XRD, N2 adsorption, NH3-TPD, SEM, 27Al MAS NMR, pyridine-FTIR and CHNS analysis. According to the results of characterization, the seeding-crystallization method was helpful in reducing the size of the crystal particles, and improving the crystallinity and dispersity of crystal particles. The surface area, especially the external surface area, pore volume and size were increased, and the total acidity was increased. The strong acid sites were transformed into medium strong acid sites, and the strength of the medium strong and strong acid was weakened. Therefore, the formation of coke was retarded, and the pentaerythritol conversion, the pentaerythrityl tetrastearate selectivity and the catalytic stability were obviously improved.

-

Gruen,Jeanneret

, p. 1798,1805 (1959)

-

PREPARATION OF TETRAESTER OF PENTAERYTHRITOL HAVING A LOW ACID VALUE AND A SMALL TIME-LAPSE CHANGE OF THE ACID VALUE

-

Paragraph 0051-0059, (2019/03/09)

The present invention provides a preparation method of tetraester of pentaerythritol, which comprises the following steps of: (1) enabling pentaerythritol, a fatty acid, or ester thereof to react under existence of an acid catalyst; (2) neutralizing the acid catalyst by adding hydrotalcite to a reaction mixture that is resulted; and (3) filtering the resulted reaction mixture. According to the present invention, the preparation method can provide tetraester of pentaerythritol having a low acid value and a small time-lapse change of the acid value with great quality, and further, can be applied to technological mass production by being improved to be more economical and eco-friendly.

COPYRIGHT KIPO 2019